| Model | Working Pressure | Air Delivery | Motor Power | Dimension(mm) | Weight(kg) | Output pipe Diameter | ||||||||

| psig | bar | cfm | m3/min | kw/hp | L | W | H | |||||||

| ZRCW-25SA | 100 | 7 | 109.5 | 3.1 | 18.5/25 | 1600 | 910 | 1350 | 840 | 1" | ||||

| 116 | 8 | 102.4 | 2.9 | |||||||||||

| 145 | 10 | 95.4 | 2.7 | |||||||||||

| 181 | 12.5 | 81.2 | 2.3 | |||||||||||

| ZRCW-30SA | 100 | 7 | 134.2 | 3.8 | 22/30 | 1450 | 1000 | 1560 | 870 | 1" | ||||

| 116 | 8 | 127.1 | 3.6 | |||||||||||

| 145 | 10 | 113.0 | 3.2 | |||||||||||

| 181 | 12.5 | 88.3 | 2.5 | |||||||||||

| ZRCW-40SA | 100 | 7 | 187.1 | 5.3 | 30/40 | 1950 | 1050 | 1432 | 980 | 11/4" | ||||

| 116 | 8 | 176.6 | 5.0 | |||||||||||

| 145 | 10 | 151.8 | 4.3 | |||||||||||

| 181 | 12.5 | 127.1 | 3.6 | |||||||||||

| ZRCW-50SA | 100 | 7 | 223.0 | 6.6 | 37/50 | 1700 | 1100 | 1630 | 1000 | 11/4" | ||||

| 116 | 8 | 218.9 | 6.2 | |||||||||||

| 145 | 10 | 201.3 | 5.7 | |||||||||||

| 181 | 12.5 | 162.4 | 4.6 | |||||||||||

| ZRCW-60SA | 100 | 7 | 282.7 | 8.0 | 45/60 | 2150 | 1300 | 1590 | 1060 | 11/2" | ||||

| 116 | 8 | 271.9 | 7.7 | |||||||||||

| 145 | 10 | 243.6 | 6.9 | |||||||||||

| 181 | 12.5 | 211.9 | 6.0 | |||||||||||

| ZRCW-75SW | 100 | 7 | 370.8 | 10.5 | 55/75 | 2200 | 1400 | 1540 | 1250 | 2" | ||||

| 116 | 8 | 346.0 | 9.8 | |||||||||||

| 145 | 10 | 307.2 | 8.7 | |||||||||||

| 181 | 12.5 | 257.8 | 7.3 | |||||||||||

| ZRCW-100SW | 100 | 7 | 480.2 | 13.6 | 75/100 | 2400 | 1450 | 1740 | 1480 | 2" | ||||

| 116 | 8 | 459.0 | 13.0 | |||||||||||

| 145 | 10 | 109.6 | 11.6 | |||||||||||

| ZRCW-120SW | 100 | 7 | 572.0 | 16.2 | 90/120 | 2550 | 1400 | 1650 | 2030 | DN50 | ||||

| 116 | 8 | 547.3 | 15.5 | |||||||||||

| 145 | 10 | 494.3 | 14.0 | |||||||||||

| ZRCW-150SW | 100 | 7 | 734.4 | 20.8 | 110/150 | 2700 | 1550 | 1750 | 2450 | DN65 | ||||

| 116 | 8 | 688.5 | 19.5 | |||||||||||

| 145 | 10 | 582.6 | 16.5 | |||||||||||

| ZRCW-175SW | 100 | 7 | 847.4 | 24.0 | 132/175 | 2600 | 1650 | 1750 | 2850 | DN65 | ||||

| 116 | 8 | 812.1 | 23.0 | |||||||||||

| 145 | 10 | 706.2 | 20.0 | |||||||||||

| ZRCW-200SW | 100 | 7 | 981.6 | 27.8 | 160/200 | 3300 | 2200 | 2000 | 3750 | DN65 | ||||

| 116 | 8 | 935.7 | 26.5 | |||||||||||

| 145 | 10 | 829.8 | 23.5 | |||||||||||

| ZRCW-270SW | 100 | 7 | 1218.2 | 34.5 | 200/270 | 3300 | 2200 | 2000 | 4100 | DN80 | ||||

| 116 | 8 | 1165.2 | 33.0 | |||||||||||

| 145 | 10 | 988.7 | 28.0 | |||||||||||

| ZRCW-330SW | 100 | 7 | 1518.3 | 43.0 | 250/330 | 3670 | 2070 | 2370 | 4750 | DN100 | ||||

| 116 | 8 | 1412.4 | 40.0 | |||||||||||

| 145 | 10 | 1306.5 | 37.0 | |||||||||||

| Motor Efficiency Class: Ultraefficient/IE3/IE2 as per your required Motor Protection Class: IP23/IP54/IP55 or as per your required Certification: CE/ISO9001/TUV/UL/SGS/ASME Voltage: 380V/3PH/50HZ/60HZ, 220V/3PH/50HZ/60HZ, 400V/3PH/50HZ/60HZ, 440V/3PH/50HZ/60HZ, 415V/3PH/50HZ/60HZ, 230V/3PH/50HZ/60HZ, dual voltage is also ok |

||||||||||||||

Oil free screw air compressor are widely used in industries that require high quality air sources such as: pharmaceutical, food, electronics, chemical, packaging, etc. 100% pure compressed air is a necessary procedure to guarantee satisfactory crafts and product quality, which ensures the production of high-end products safely and risk-free.

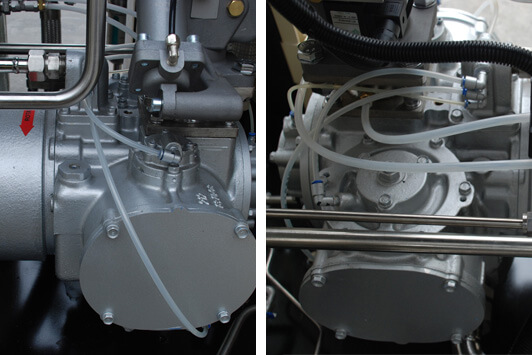

Oil-free water-lubricated air compressors are generally screw-type air compressors, mainly using water agent lubricants to perform lubrication. During the working process, the lubrication, sealing and cooling of the entire main machine are all done by water.

Features:

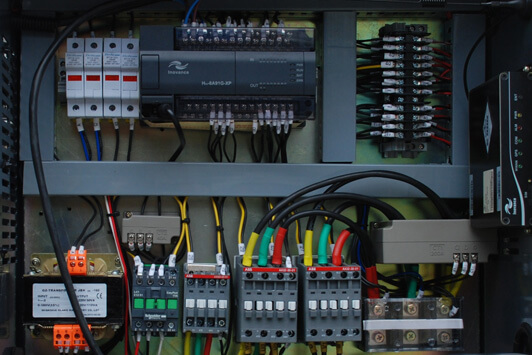

ABB high sensitivity high reliability, low failure.

Direct connect with high transmission efficiency .

Clear at a glance

The operation is simple ,thoughtful and powerful.

Copper material,high thermal effects,Ensure isothermal compression,it can work high-temperature conditions,the maximum temperature<45℃ in summer The lowest temperature in winter is +10.

Lightweight structure,but the structure strength is far greater than axial flow fan,good dynamic balance performance,it has low vibration,low noise,centrifugal fan aerodynamic performance is better than that of axial flow fan,low power consumption,high efficiency and reliable running life.Configuration on the screw air compressor is an excellent choice.

Advantages:

-

True Energy Saving:

Oil free water lubrication screw air compressor is a kind of compressor that provides clean, pollution-free, 100% oil free screw air compressor, its zero emission can protect the environment efficiently.

True Energy Saving ---- Lubrication, Sealing and Cooling:

Ideal isothermal compression : High efficiency (large air delivery)

Low temperature compression : No need the intercooler and after cooler

Low rotation speed : Low noise, low vibration and no need the overdrive gear

Low viscosity of lubrication water : Easy to be separated with the air

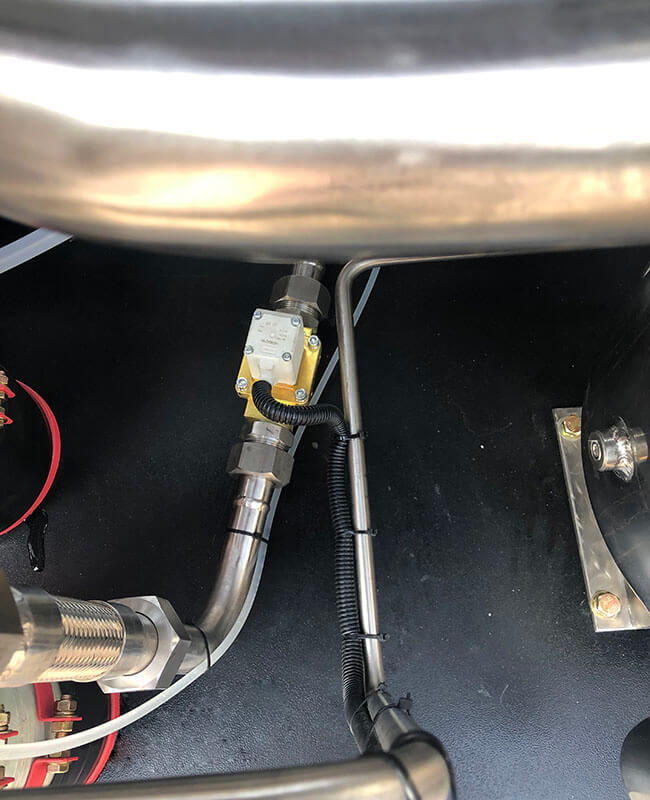

All stainless steel pipe:

Simple ,non-corrosive,non-polluting,high reliablity

Single Stage Compression ,High Efficiency ,and Energy Saving ,and Easy Maintenance:

Single stage compression makes the structure easy.

Compression efficiency is higher than the two stage dry air compressor.

Less consumable parts, easy to be disassembled, reduce the maintenance cost and time greatly.

Application:

About Elang:

FAQ:

-

Q1.Why customer choose us?

A:ELANG INDUSTRIAL (SHANGHAI) CO., LTD., with 20 years old history, we are specialized in Rotary Screw Air Compressor. Germany Standard and over 10 years exporting experience help us won more than 50 loyal foreign agents. We warmly welcome your small trial order for quality or market test.

Q2.Are you a manufacturer or trading company?

A:We are professional manufacturer with big modern factory in Shanghai,China.Both OEM & ODM service can be accepted.

Q3.What’s your delivery time?

A:Generally 3 to 7 days, if urgently order, pls contact our sales in advance.

Q4.How long is your air compressor warranty?

A:One year for the whole machine and five years for screw air end, except consumble spare parts.

Q5.How long could your air compressor be used?

A:Generally, more than 10 years.

Q6. What's payment term?

A: T/T, L/C, D/P, Western Union, Paypal, Credit Card, and etc.

Also we could accept USD, RMB, Euro and other currency.

Q7.How about your customer service?

A:24 hours on-line service available. 48hours global problem sovled promise.

10+ professional overseas technical service team.

Q8.How about your after-sales service?

A:1. Provide customers with intallation and commissioning online instructions.

2. Well-trained engineers available to overseas service.

3. Worldwide agents and after service avaiable.arrange our engineers to help you training and installation.