Oil Free Screw Air Compressor

Oil free screw air compressor are widely used in industries that require high quality air sources such as: pharmaceutical, food, electronics, chemical, packaging, etc. 100% pure compressed air is a necessary procedure to guarantee satisfactory crafts and product quality, which ensures the production of high-end products safely and risk-free.

Oil-free water-lubricated air compressors are generally screw-type air compressors, mainly using water agent lubricants to perform lubrication. During the working process, the lubrication, sealing and cooling of the entire main machine are all done by water.

Features:

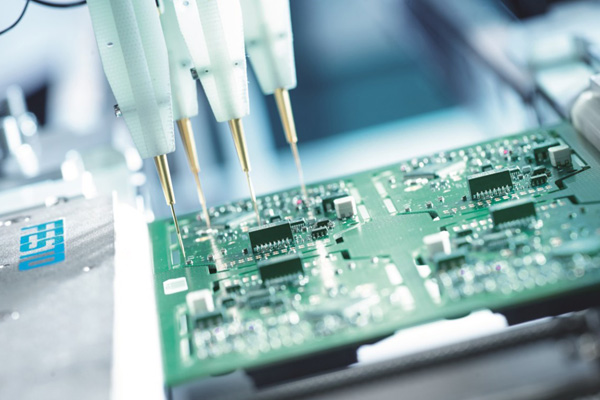

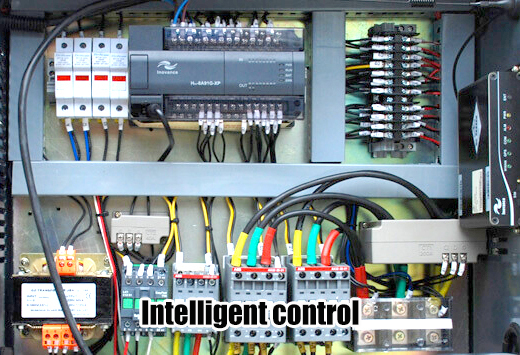

Intelligent control:

ABB high sensitivity high reliability, low failure.

Motor and air end:

Direct connect with high transmission efficiency .

Clear at a glance

The operation is simple ,thoughtful and powerful.

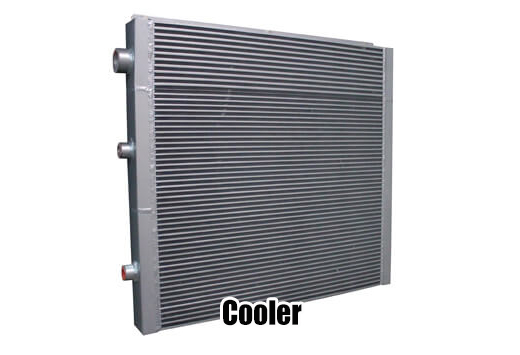

Cooler:

Copper material,high thermal effects,Ensure isothermal compression,it can work high-temperature conditions,the maximum temperature<45℃ in summer The lowest temperature in winter is +10.

Lightweight structure,but the structure strength is far greater than axial flow fan,good dynamic balance performance,it has low vibration,low noise,centrifugal fan aerodynamic performance is better than that of axial flow fan,low power consumption,high efficiency and reliable running life.Configuration on the screw air compressor is an excellent choice.

Advantages:

True Energy Saving:

Oil free water lubrication screw air compressor is a kind of compressor that provides clean, pollution-free, 100% oil free screw air compressor, its zero emission can protect the environment efficiently.

True Energy Saving ---- Lubrication, Sealing and Cooling:

Ideal isothermal compression : High efficiency (large air delivery)

Low temperature compression : No need the intercooler and after cooler

Low rotation speed : Low noise, low vibration and no need the overdrive gear

Low viscosity of lubrication water : Easy to be separated with the air

| Model | Working Pressure | Air Delivery | Motor Power | Dimension(mm) | Weight(kg) | Output pipe Diameter | ||||||||

| psig | bar | cfm | m3/min | kw/hp | L | W | H | |||||||

| ZRCW-25SA | 100 | 7 | 109.5 | 3.1 | 18.5/25 | 1600 | 910 | 1350 | 840 | 1" | ||||

| 116 | 8 | 102.4 | 2.9 | |||||||||||

| 145 | 10 | 95.4 | 2.7 | |||||||||||

| 181 | 12.5 | 81.2 | 2.3 | |||||||||||

| ZRCW-30SA | 100 | 7 | 134.2 | 3.8 | 22/30 | 1450 | 1000 | 1560 | 840 | 1" | ||||

| 116 | 8 | 127.1 | 3.6 | |||||||||||

| 145 | 10 | 113.0 | 3.2 | |||||||||||

| 181 | 12.5 | 88.3 | 2.5 | |||||||||||

| ZRCW-40SA | 100 | 7 | 187.1 | 5.3 | 30/40 | 1950 | 1050 | 1432 | 980 | 11/4" | ||||

| 116 | 8 | 176.6 | 5.0 | |||||||||||

| 145 | 10 | 151.8 | 4.3 | |||||||||||

| 181 | 12.5 | 127.1 | 3.6 | |||||||||||

| ZRCW-50SA | 100 | 7 | 223.0 | 6.6 | 37/50 | 1700 | 1100 | 1630 | 1000 | 11/4" | ||||

| 116 | 8 | 218.9 | 6.2 | |||||||||||

| 145 | 10 | 201.3 | 5.7 | |||||||||||

| 181 | 12.5 | 162.4 | 4.6 | |||||||||||

| ZRCW-60SA | 100 | 7 | 282.7 | 8.0 | 45/60 | 2150 | 1300 | 1590 | 1060 | 11/2" | ||||

| 116 | 8 | 271.9 | 7.7 | |||||||||||

| 145 | 10 | 243.6 | 6.9 | |||||||||||

| 181 | 12.5 | 211.9 | 6.0 | |||||||||||

| ZRCW-75SW | 100 | 7 | 370.8 | 10.5 | 55/75 | 2200 | 1400 | 1540 | 1250 | 2" | ||||

| 116 | 8 | 346.0 | 9.8 | |||||||||||

| 145 | 10 | 307.2 | 8.7 | |||||||||||

| 181 | 12.5 | 257.8 | 7.3 | |||||||||||

| ZRCW-100SW | 100 | 7 | 480.2 | 13.6 | 75/100 | 2400 | 1450 | 1740 | 1480 | 2" | ||||

| 116 | 8 | 459.0 | 13.0 | |||||||||||

| 145 | 10 | 109.6 | 11.6 | |||||||||||

| ZRCW-120SW | 100 | 7 | 572.0 | 16.2 | 90/120 | 2550 | 1400 | 1650 | 2030 | DN50 | ||||

| 116 | 8 | 547.3 | 15.5 | |||||||||||

| 145 | 10 | 494.3 | 14.0 | |||||||||||

| ZRCW-150SW | 100 | 7 | 734.4 | 20.8 | 110/150 | 2700 | 1550 | 1750 | 2450 | DN65 | ||||

| 116 | 8 | 688.5 | 19.5 | |||||||||||

| 145 | 10 | 582.6 | 16.5 | |||||||||||

| ZRCW-175SW | 100 | 7 | 847.4 | 24.0 | 132/175 | 2600 | 1650 | 1750 | 2850 | DN65 | ||||

| 116 | 8 | 812.1 | 23.0 | |||||||||||

| 145 | 10 | 706.2 | 20.0 | |||||||||||

| ZRCW-200SW | 100 | 7 | 981.6 | 27.8 | 160/200 | 3300 | 2200 | 2000 | 4400 | DN80 | ||||

| 116 | 8 | 935.7 | 26.5 | |||||||||||

| 145 | 10 | 829.8 | 23.5 | |||||||||||

| ZRCW-270SW | 100 | 7 | 1218.2 | 34.5 | 200/270 | 2850 | 1700 | 2000 | 4400 | DN80 | ||||

| 116 | 8 | 1165.2 | 33.0 | |||||||||||

| 145 | 10 | 988.7 | 28.0 | |||||||||||

| ZRCW-330SW | 100 | 7 | 1518.3 | 43.0 | 250/330 | 3150 | 2000 | 2120 | 4400 | DN80 | ||||

| 116 | 8 | 1412.4 | 40.0 | |||||||||||

| 145 | 10 | 1306.5 | 37.0 | |||||||||||

|

Motor Efficiency Class: Ultraefficient/IE3/IE2 as per your required Motor Protection Class: IP23/IP54/IP55 or as per your required Certification: CE/ISO9001/TUV/UL/SGS/ASME Voltage: 380V/3PH/50HZ/60HZ, 220V/3PH/50HZ/60HZ, 400V/3PH/50HZ/60HZ, 440V/3PH/50HZ/60HZ, 415V/3PH/50HZ/60HZ, 230V/3PH/50HZ/60HZ, dual voltage is also ok |

||||||||||||||